Mb Crusher - Overview

B has been THE world leader for over 15 year

For over 15 years MB has been a leader in the fields of crushing, demolition and recycling, by designing, producing and selling the very first jaw bucket crusher.

Since 2001, MB has offered the largest line of patented crusher buckets all over the world. With extensive innovation and development, MB now offers crusher buckets for excavators, skid loaders, and backhoes of all sizes.

The values of the family owned business have enabled MB to reach levels of internationally recognized excellence: founded and headquartered in Italy, the company establishes itself globally through 7 international subsidiaries with logistic centers located on different continents, as well as an extensive network of authorized dealers and service support throughout the world.

The biggest advantage at MB is the quality of its organization. Inside the new MB Headquarters, with a total area of over 180,000 square feet, MB manages all phases, from research and development to production to sales. The company controls the complete supply chain to ensure the products are of the highest “Made in Italy” quality.

MB always looks forward to the future through the development of new tools and accessories to satisfy customers’ needs.

MB is a leading manufacturer of equipment, machinery and accessories for the construction, demolition and recycling industries. Applicable to any type of excavator, MB products are the most effective means in constructions and excavations, but also in special applications such as quarries, mines and environmental rehabilitations, for crushing, screening and separating inert materials directly on site to reuse it or allocate it to other uses. Crusher bucket, screening bucket, iron separator and quick coupling are an ever-expanding range of products strictly certified, whose use reduce costs, processing times and transportation of materials, while contributing to the environment.

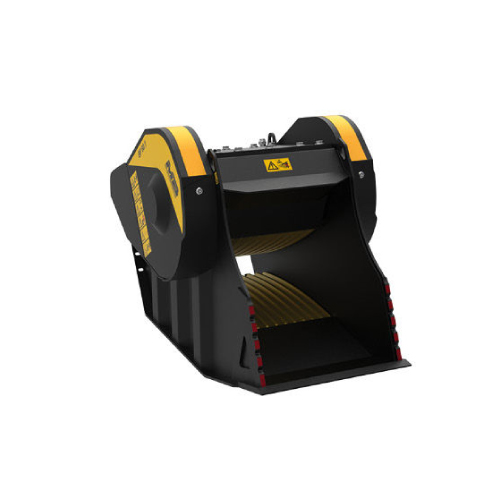

Product Line

- It crushes all types of inert waste material

- It crushes materials directly on site

- It reduces the use of mechanical pieces of equipment

- It eliminates all leasing costs

- It cuts down on transportation and management costs

- It is comfortable, simple to use and fast

- Suited for small and large worksites

- It allows materials to be recycled, resulting in significant savings

- It solves the problem of having to dispose of demolition materials by taking them to a dump

Models

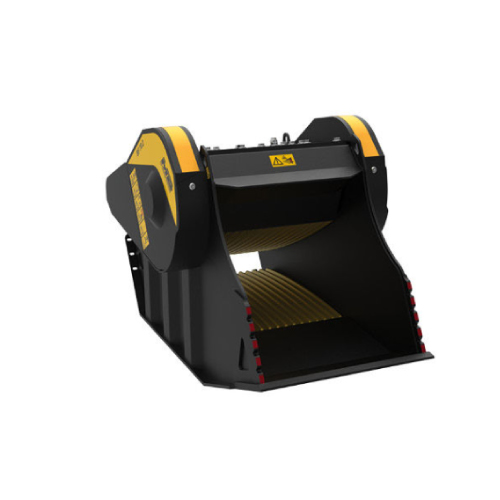

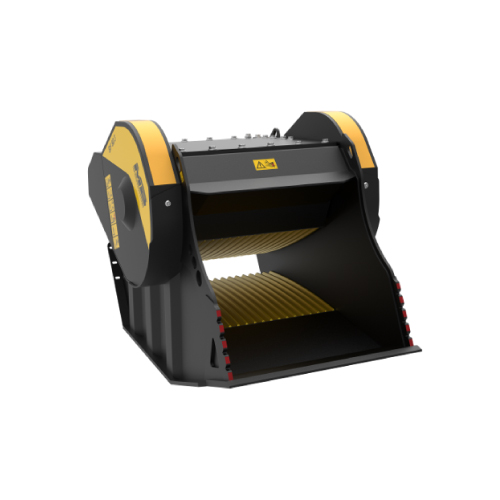

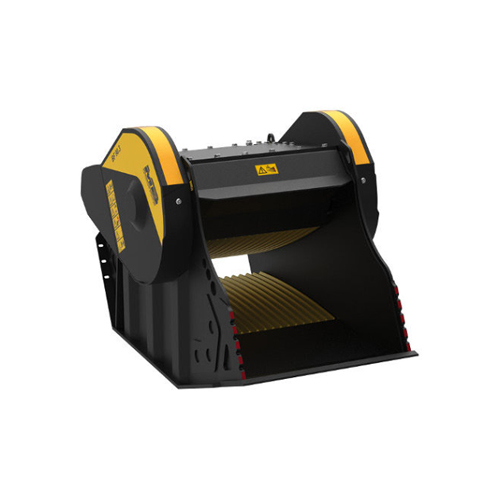

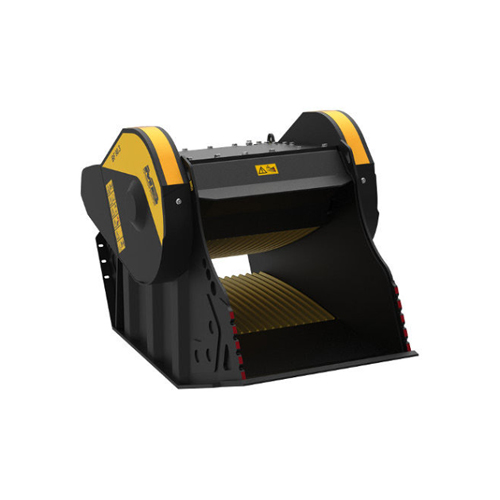

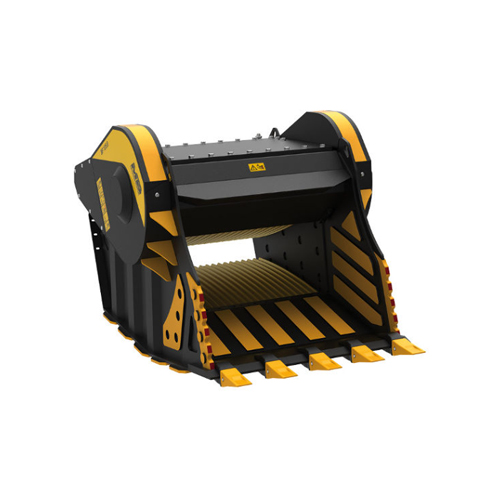

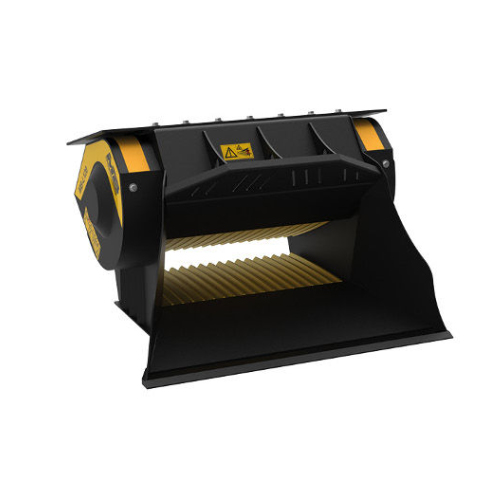

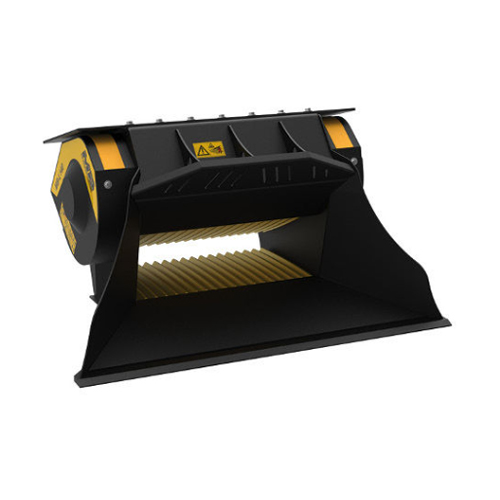

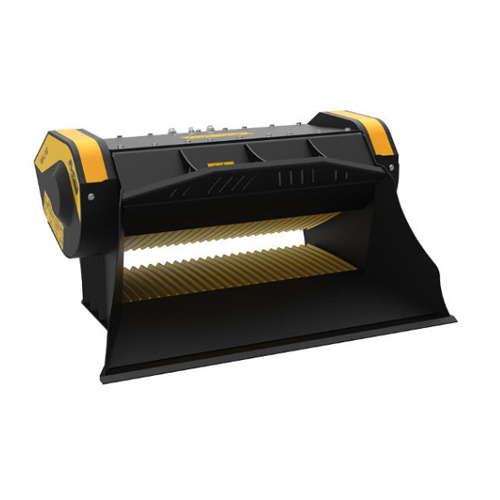

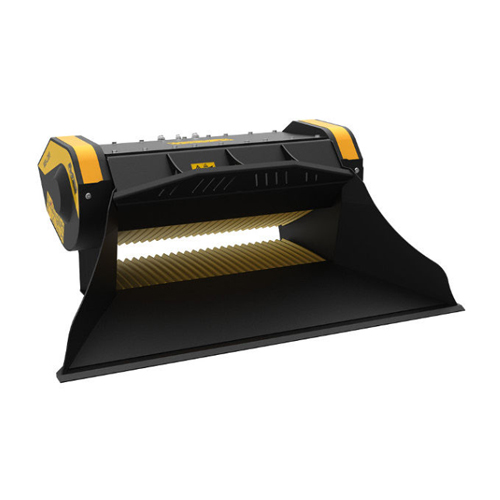

Perfect for on-site crushing of inert materials and the first one of its kind to be introduced on the market, the MB Crusher Bucket is a piece of equipment that works by taking advantage of the hydraulic system of the excavators, skid loader, loader and backhoe loaders to which it is fitted.

It has many areas of applications: from building demolitions in general, to the requalification of former industrial and urban areas to the processing of excavation materials, from the earth movement sector to road works, from quarries to mines, from environmental reclamation to applications on rocky soil.